Roadrunner Engineering News

![]()

PO Box 53296- Albuquerque, NM 87153

Phone/Fax (505) 296-7678

E-mail:

RoadrunnerEngr@msn.com

Website:

www.roadrunnerengineering.com

3x2’s vs. 4x2’s

Contest Results

Langford 284 cu.in. Flathead Ford Engine

Dyno Tested 8/11-8/14/2010, Albuquerque,

NM

The contest consisted of

the participants estimating the peak horsepower for a 284 cu.in. street flathead

when tested with an Offenhauser 3x2 setup and a Weiand 4x2 setup. The

carburetors were identical Stromberg 97’s, except for the jetting which was

optimized for peak power with each setup. A summary of

the complete engine and the test series

is given later in this newsletter.

The official numbers for determining the contest

winners were 211 hp for the 3x2 setup and 209 hp for the 4x2 setup.

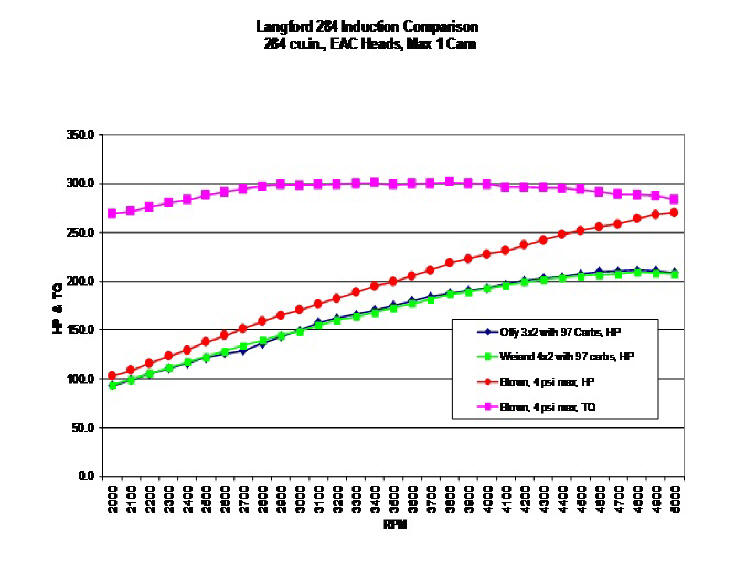

A plot of the dyno results is given

below. Note that the results were essentially identical (within the accuracy of

the dyno) for both setups for this particular engine.

Nobody correctly estimated

the results exactly but two contestants came very close.

The winner of the $50 was Jay Hertz who

estimated 212 and 214 hp. The runner-up was Bob Higgins who estimated 210 and

204 hp. The total difference was the same for these entries, but Jay’s entry

was earlier. Bob will get a $25 prize. The runner ups were Alan Samura, Fred

Edeskuty, and Scott Yockstick, who will receive the

335 HP Flathead Ford Performance Handbook. Thanks to all who entered! We

will have more contests and I welcome suggestions.

The engine was built to

produce a strong, reliable street engine. Automotive Machine Service in

Albuquerque, NM did part of the machine work. Gary McGlasson of McGlasson Racing

Engines, Albuquerque, NM built, tested and tuned the engine including the

porting and relieving of the block. Gary also performed the head modifications.

The engine was built per the guidelines in

335 HP Flathead Ford Performance Handbook.

The engine was

subjected to 35+ dyno runs (“pulls”) over the test period. The first series of

pulls was performed normally aspirated to break-in the engine, do initial tuning

and check for proper function of all components. Normally aspirated the engine

made about 210 HP peak at 4800 rpm with both the 3x2 and 4x2 manifolds.

Supercharged, the engine produced 270 HP peak at the

maximum 5000 test rpm with about 4 psi boost. The boost level was limited to

allow safe operation at sea level with the 7.3:1 compression ratio and 91-octane

fuel.

Measured torque &

horsepower curves for this strong 284 cu.in. flathead

engine are shown in a plot at the end of

this report. All testing

was performed with an alternator (or simulator) and the water pumps installed

using 91-octane premium pump gas.

All power values are corrected to standard dyno (sea level) conditions of 60 F

and 29.92 in.Hg.

The engine characteristics

and test discussion follow below.

8BA Short block assembly

a) 3-5/16” bore, Ross

forged pistons with stock dome and metric rings (1.5 mm, 1.5 mm, 3 mm width).

b) 4-1/8” inch-stroke Scat

crank, H-beam rods, mild steel center main cap.

c) Manley 1.6” stainless

intake and exhaust valves, block ported and relieved.

d) Melling M19 standard

volume oil pump.

e) Iskenderian Max1 cam

with single Isky 185G valve springs, shimmed as necessary to get a seated force

of 70-85 lbs. Valve clearance was .012 (intake) and .014 (exhaust).

Heads

Mercury EAC iron heads with

an 81 cc head volume were used. These were prepared by Gary McGlasson and

configured for a supercharged flathead designed to operate at sea level with

moderate boost and premium pump gas.

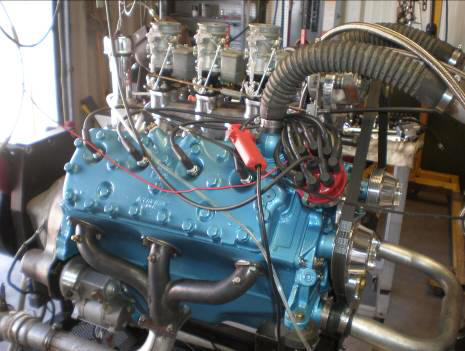

Intake-Normally

Aspirated

Offenhauser 3x2 and Weiand

4x2 intake manifolds were used for break-in and normally aspirated testing.

Stromberg 97 carburetors prepared by Jere Jobe of Vintage Carburetion Technology

Inc. in Somers, MT were used on both manifolds.

Intake-Supercharged

A Roadrunner single-plane

blower manifold and a Weiand 142 blower with 50% overdrive pulleys were used for

the supercharged tests. A 570 cfm Holley Street Avenger (4-bbl) carburetor with

vacuum secondaries was used for supercharged testing and will be used on the

street. No air cleaner was used during testing. A large capacity air cleaner

will be used in service.

Exhaust

Free flowing center-dump

headers and large (4” inlet/exhaust) truck mufflers were used during all tests.

The engine had no center exhaust baffles.

Ignition

A top mount electronic

Mallory distributor with mechanical advance and Autolite 216 spark plugs gapped

at .035 were used for test. which was all in by 3600 rpm. Total advance was

limited to 26 degrees maximum for normally aspirated testing and 20 degrees

maximum for supercharged testing.

For supercharged street

use, an ignition retard device such as those available from MSD (P/N’s 5462 or

6462) with a retard setting of 1-2 degrees per psi of boost is recommended to

allow the total timing to be set to 24-28 degrees for part load cruising

economy.

Water pumps

Stock 8A type new pumps

with modern seals and bearings were used along with Roadrunner serpentine

pulleys and hubs for all tests.

An automatic belt tensioner was used for all supercharged testing. The automatic unit provides better belt wrap on the crank and maintenance free operation.

Discussion

For supercharged testing, a Holley 570 cfm Street Avenger 4-bbl was used. The stock jet sizes are #54 in the primaries and #65 in the secondaries. This produced an average peak power reading of 265 hp. Leaning out the mixture with #52 and #63 jets upped the average peak to 270 hp at the 5300 ft test altitude. The stock jets were reinstalled to obtain a safe air-fuel mixture at the lower use altitude.

It is always prudent to go with a somewhat rich mixture (11.5:1 or less) for supercharged engines since the rich mixture gives an inter-cooling effect and reduces detonation tendencies with little if any loss of power.

All supercharged tests were run with a 3.75” diameter supercharger pulley and a 5.625” crankshaft pulley. This produced peak boost readings of 4 psi or less (corrected) at full throttle. The engine will be delivered with these pulleys installed to assure fuel compatibility during cross-country driving at low altitude. There is certainly room to grow here if the owner so desires. More boost and higher rpm could have put this engine over 300 hp but with some penalty in reliability.

Overall, this engine performed like a champ on the dyno. Please contact Roadrunner Engineering if you require further information.

Below. Three Stromberg 97’s on an Offenhauser Manifold

Below. Four Stromberg 97’s on a Weiand Manifold

Roadrunner Kit with a Weiand 142 Blower and a Holley Street Avenger 4-bbl Installed.

Deposits and worksheets are currently being accepted for the last run of

Roadrunner supercharger kits for the flathead Ford. A limited number of orders

are being accepted and delivery is on a first come, first served basis. Orders

require a $500 deposit and a completed worksheet (download from

www.roadrunnerengineering.com ). Also see the website for the current

kit prices.

For more info on the

books below go to

www.roadrunnerengineering.com . Blown Flathead has been out of print

for some time, but a limited number are available from Speedway Motors and

Roadrunner.